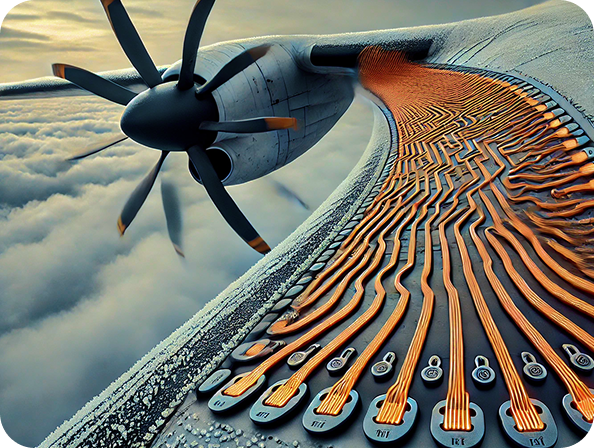

Preventing excessive ice buildup on aircraft wings during flight is critical. Traditionally, heat for this purpose is sourced from the aircraft’s engines and distributed through pneumatic channels, or in aircraft where this is not feasible, pneumatic de-icers that mechanically break the ice are used.

However, the need for lighter de-icing products to improve fuel efficiency has increased interest in using electrically generated heat for this task. Since aircraft operate in environments with high humidity and low ambient temperatures, airflow rapidly absorbs heat from the wing surface, making the electro-thermal anti-icing system a challenging application.